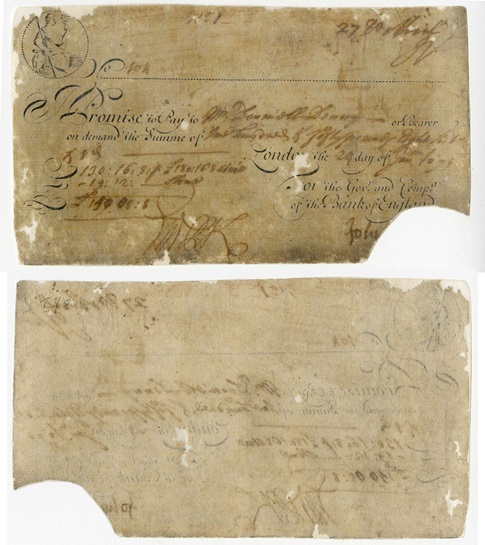

24 January 1699

Banknote

Printed features, like the Britannia medallion and the ‘promise to pay’ on this example, began to be included on Bank of England notes in the late 1600s.

These features were printed offsite by a private firm based in London but little is known about their production.

Bank of England, banknote, 24 January 1699, I/008

1791

The Old Bank of England

By 1791, sending printing plates and banknote paper outside of the Bank’s own premises was becoming too risky.

Although a private firm continued to print the notes, the Bank moved production into their Threadneedle Street building in London. However, the demand for banknotes continued to increase.

Thomas Homer Shepherd, The Old Bank of England, c.1800, 0803

1808

Sir John Soane's extension

By 1805, there were 27 printing presses being operated by over 50 men at the Bank’s building in Threadneedle Street.

Some of the men there got ill because of the cramped working conditions. In 1808, Printing Works was moved into a new extension of the building designed by the architect, Sir John Soane.

Unknown, The Bank of England (showing Sir John Soane’s extension), 1827, 0084

1808

Banknote production taken into the hands of the Bank

At the same time, the Bank’s governing board decided that production should not depend on a private firm for security reasons.

So the banknote Printing Works was ‘taken into the hands of the Bank’.

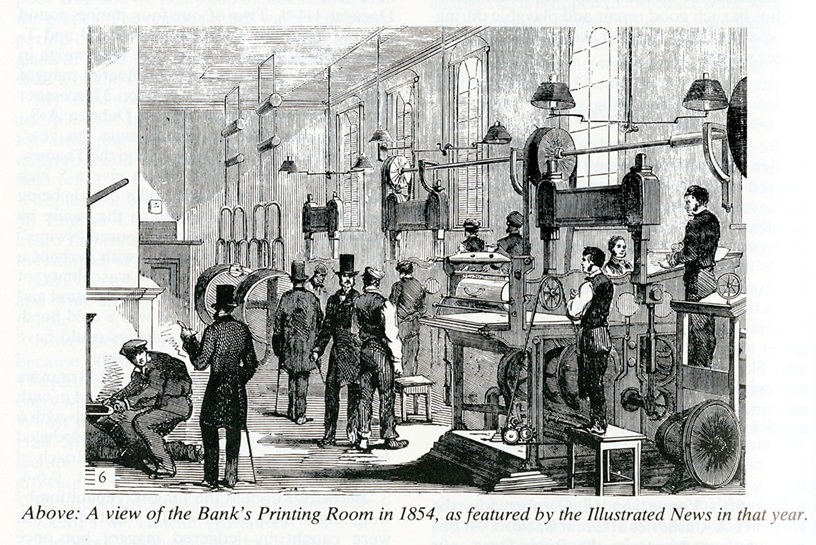

Unknown, ‘View of the Bank's printing room in 1854 as featured in the Illustrated London News’, Britannia Quarterly, 1980, Bank of England Archive: PW1/31

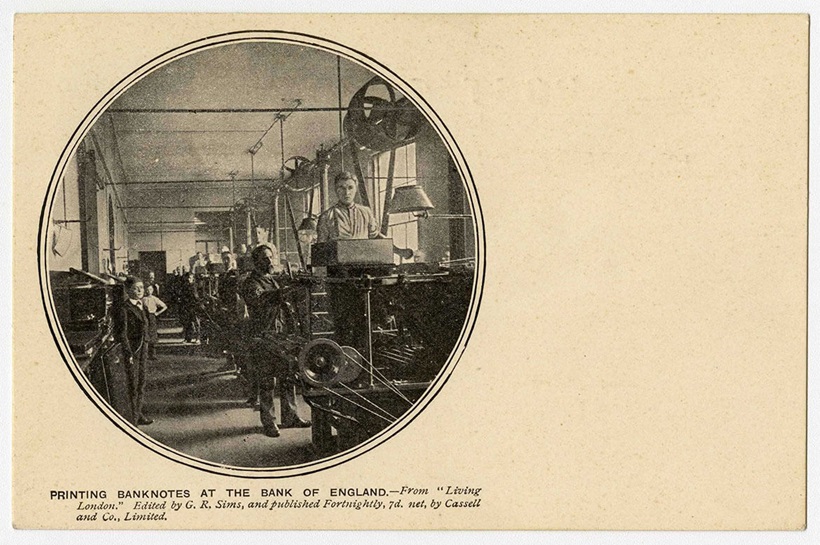

1900s

Printing department at Threadneedle Street

Banknotes continued to be printed in Threadneedle Street throughout the 1800s.

The Bank employed boys in their Printing Works until a 1918 Education Act made education compulsory up until 14 years old.

Unknown, Postcard depicting interior of the printing department at Threadneedle Street c.1900, 1989, 1989/210/13

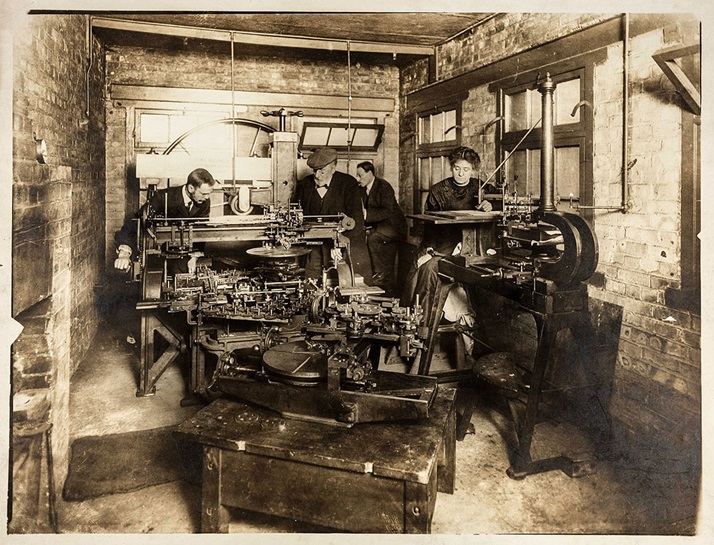

1914 to 1918

Printing works at Tabernacle Street

During the First World War, there was an increased demand for banknotes and other official printed products.

The Bank leased two buildings nearby in Tabernacle Street and moved its dividend book, warrant and envelope printing here.

Unknown, photograph showing the Bank’s printing works at Tabernacle Street, 1915, Bank of England Archive: 15A12/6/3/1

1917

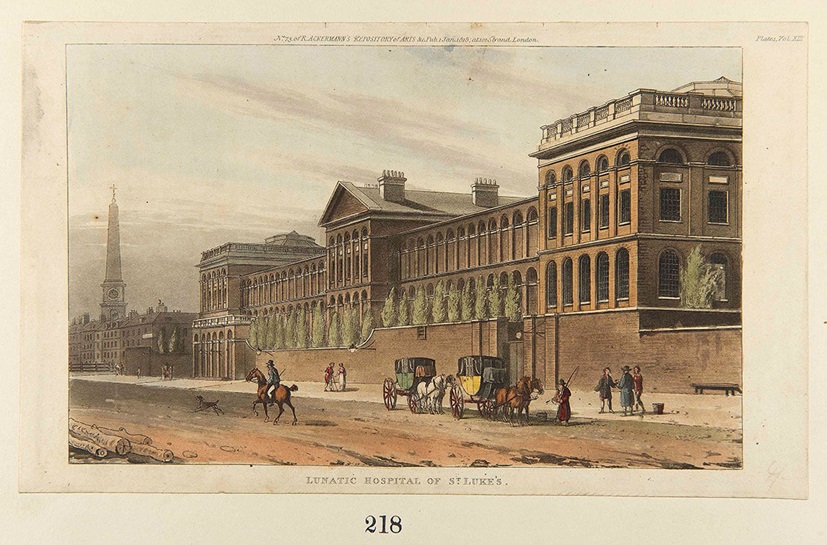

The Lunatic Hospital of St Luke's

In 1917, the Bank moved its Printing Works out of Threadneedle Street.

The new site was the former St Luke’s Hospital for Lunatics in Old Street, which the Bank had purchased the year before. The hospital was designed in the 1780s by architect George Dance and had an impressive 150 metre frontage.

Unknown, The Lunatic Hospital of St Luke’s, 1815, 0218

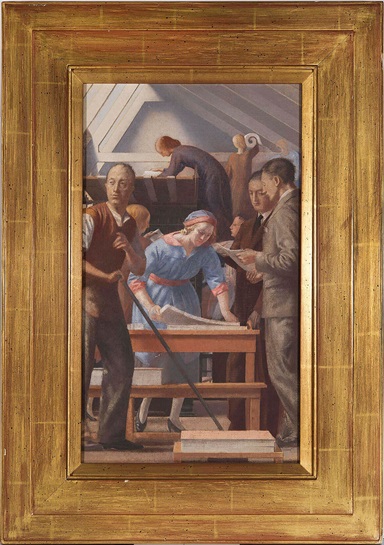

1920

St Luke's Printing Works

By 1920, the hospital was converted into a state of the art facility by the architect F. W. Troup.

It was equipped with concrete floors, three large machinery halls and amenities for staff. At the time, it was described as ‘a model of what an up-to-date printing factory should be.’

Walter Thomas Monnington, St Luke’s Printing Works, c.1930. 1994/197/001

1938

Printing Works at Overton, Hampshire

During the Second World War, the Bank moved the Printing Works to the countryside to protect banknote production from the threat of German bombs.

A factory was set up at Overton in Hampshire and production at St Luke’s was paused until after the war in 1945.

Unknown, photograph of note Printing machine at Overton, 1942, Bank of England Archive: 15A13/15/131

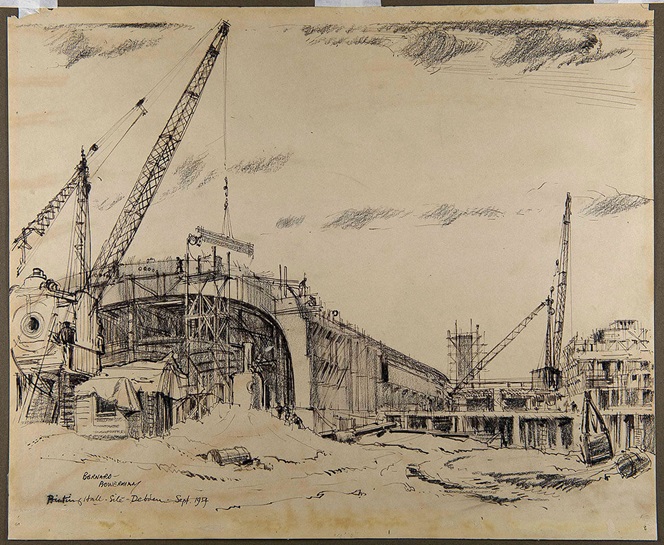

1954

Printing Hall Site Debden

Ten years later, the Printing Works at St Luke’s was working at full capacity.

The printing halls, strong rooms and staff facilities were badly overcrowded. The Bank decided to build a new banknote printing factory in Debden, Essex.

Bernard Bowerman, Printing Hall Site Debden, 1954, 1978/009